Cone Clutch Design Calculations Pdf

Also in this work efficient and reliable design of mechanical clutch is find out. Features of the DiscCone clutch include.

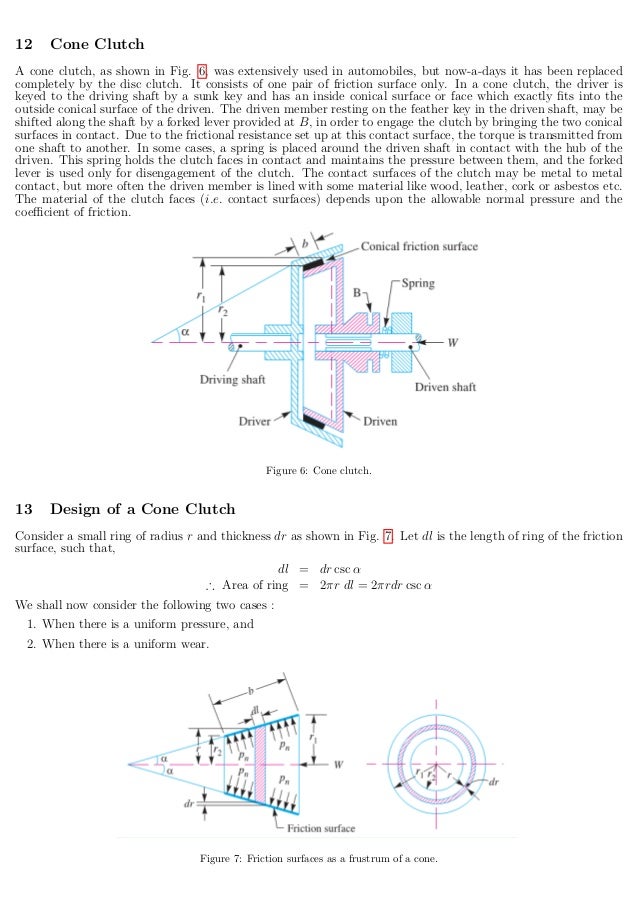

Figure 6 Consider a rotating shaft with a disc at the end that presses up against another so that rotation is transmitted from one to the other by friction.

. Design of plate clutch. Α cone angle sinα f cosα Fa August 15 2007 21 Fig. Cone Clutch Design Equations.

This article gives you all information about this clutch working application and advantages and disadvantages. Ktubtechdme2tracektuDESIGN PROBLEM FOR CONE CLUTCH - DESIGN OF MACHINE ELEMENTS - 2 MODULE 1DESIGN PROCEDURE FOR CONE CLUTCH httpsyoutubesawh6bjw. One pair of friction surface only.

Power Actuated Clutches 28. Cone Clutches Figure 4-a shows a cone clutch. The clutch applies kinetic friction torque only when one driveline axis is spinning relative to the other driveline axis.

A flat clutch is a special case of a conical clutch with an included angle of 180o. Developed in the clutch is tried to reduce with the help of software approach. Httpsscholarsarchivebyueduetd Part of the Mechanical Engineering Commons BYU ScholarsArchive Citation Crane Nathan B Compliant Centrifugal Clutches.

This clutch is used where high torque to be transfer at low rotating speed. An axial clutch is one in which the mating frictional members are moved in a direction parallel to the shaft. When you apply a normal force F N the Cone Clutch block can apply two kinds of friction kinetic and static to the driveline motion.

Clutch torque capacity calculation. Design Calculations A single disk Kevlar 29 friction clutch plate was designed to transmit a power of. This is the special case of the cone clutch when β 90o and sinβ 1.

As we have mention in earlier section of this article cone clutch is a one type of friction clutch. Small axial force is required to keep the clutch engaged. The calculation process of automobile friction disc clutch assembly has been aided via the creation of a special computer program.

The theory is the same as for the disk clutch but with an effective coefficient of friction. Clutch Operating Linkage 27. Normal force acting on the clutch.

Clutches namely disc or plate clutch single or multiple- clutch cone clutch and centrifugal clutch 6. Before starting work on the design of any machine get thoroughly familiar with. For a given dimension the torque transmitted by cone clutch is higher than that of a single plate clutch.

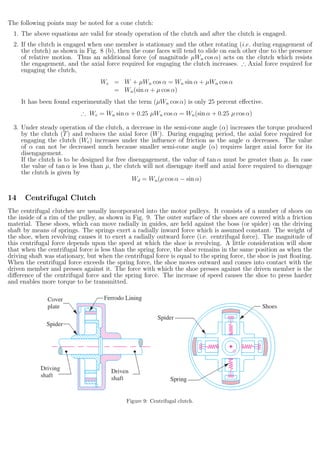

The 1200 series and the 1300 series. 2412 Design of a Cone Clutch Consider a pair of friction surfaces of a cone clutch as shown in Fig. Within the area of the friction surface we are going to represent an elementary area dx at the distance x from the center.

By angling the contacting surfaces the torque capacity is increased. The tendency to grab. The detail study of clutch and modeling of clutch is done in pro-e software and the analysis is to be done in Ansys software.

This section discusses the specialized model implemented in the Cone Clutch block. Advantages of the disk clutch include the more effective heat-dissipation surfaces the favorable pressure distribution. 168 Cone clutch geometry August 15 2007 22 Cone clutch Combining the above two equations we get sinα f cosα f r F T m a f August 15 2007 23 Example Problem 16-3.

For example for an angle of 96 the capacity is increased by a factor of 6. A 2D drawing is drafted for multi plate clutch from the calculations and a 3D model is created in the 3D modeling software ProEngineer. Design Analysis and Testing 2003.

It is similar to a disk clutch and can be regarded as the general case of which the disk clutch is a special case with a cone angle a of 90. Contact surfaces depends upon the allowable normal pressure and the coefficient of friction. Keywords- Clutch Structural Analysis Ansys.

Syllabus Department of Mechanical Engineering 2 Mod ule Topics 1 Clutches - friction clutches design considerations multiple disc clutches cone clutch centrifugal clutch. One of the earliest of these is the cone clutch which is simple in construction and quite powerful. The 1200 series has a cast iron heat dissipating.

Torques and Forces on Clutches and Brakes For the cone clutch shown determine the torque-transmitting capacity. Mechanics and Machine Design Equations and Calculators Design of Load Carrying Shaft With One Pulley Supported by two Bearings Flywheel Effect or Polar Moment of Inertia Lifting Boom Davits Application and Design Equations Large and Small Diameter Lifting Pulley Drums Two Lifting Lifting Pulleys Mechanical Advantage Multiple Pulleys Lifting Mechanical Advantage. 2 Brakes-Block brake band brake band and block brake internal expanding shoebrake 3 2 Rolling contact bearing- Design of bearings Types Selection of a bearing type bearing life static and dynamic.

The construction of a cone clutch makes it impractical to have more than one friction interface. The 1300 series offers high torque in a space saving design. It may be idealised like this.

Crane Brigham Young University - Provo Follow this and additional works at. θ cone angle to the shaft axis from 8 upwards. Number of friction elements.

To calculate the torque capacity of the clutch well have a look at the geometry of the clutch friction disc. Friction Cone Clutch 26. ConeClutches 3DirectConeClutch-Onpage4isshownarepro-ductionofadrawingofadirectconeclutchTheflywheelis boredoutontheinsiderimtoreceivetheclutchspider.

Make free-hand sketches of various ways the machine might be constructed at the same time making any preliminary calculations which might be required to. Design Analysis and Testing Nathan B. Cone Clutch Cone clutches are nothing but frictional clutches with conical surfaces.

The small cone angle causes some reluctance in disengagement. The aim of the project is to design a multi plate clutch by using empirical formulas. The material of the clutch faces ie.

When the friction clutch begins to engage slipping occurs between the contact surfaces pressure plate clutch disc and flywheel. High Torque Space-saving design No slippage Fast response based on low air consumption The DiscCone clutch is available in two models.

Design Modeling And Analysis Of Single Plate Clutch Ppt Download

Friction Clutch With Conical Plates That Engage When Normal Force Exceeds Threshold Matlab

Calculating Torque And Power Transmitted By Flat Clutches And Conical Clutches Youtube

Pdf Clutches Bambang Sugianto Academia Edu

Conical Clutch Theory Of Machines Questions And Answers Sanfoundry

Gek Wiki How To Make A Cone And Cone Calculator Cone Calculator Metal Working Cone Template

Cone Clutch Uniform Pressure Youtube

Pdf Torqueline Cone Clutch Thermo Mechanical Stability Of Cone Clutches For Ats

Pdf Design Of A Cone Clutch National Institute Of Technology Rourkela Machine Element Design Practice Labaratory Swarnendu Ganguly Academia Edu

Design Of Transmission Elements

Cone Clutch Parts Working Advantages Disadvantages Applications Pdf Clutch Cone Spring Clutches

0 Response to "Cone Clutch Design Calculations Pdf"

Post a Comment